Metal bending equipment refers to machines and tools used to shape, fold, and form metal sheets or bars into specific angles and curves. These tools range from manual devices like brake presses to advanced hydraulic and CNC machines, offering various levels of precision and power.

The primary purpose of metal bending equipment is to ensure consistent, accurate bends that meet design specifications while improving efficiency in metalworking processes. Different types of equipment are selected based on the material thickness, bend radius, and production volume.

Understanding the right equipment for a project can save time and costs while delivering reliable results. This article explores the common types of metal bending equipment and their best applications.

Types of Metal Bending Equipment

Metal bending equipment varies in complexity and operation methods. Some rely purely on manual force, while others use hydraulic power or computer control to achieve precise bends. Each type serves specific applications depending on volume, accuracy, and material thickness.

Manual Metal Bending Tools

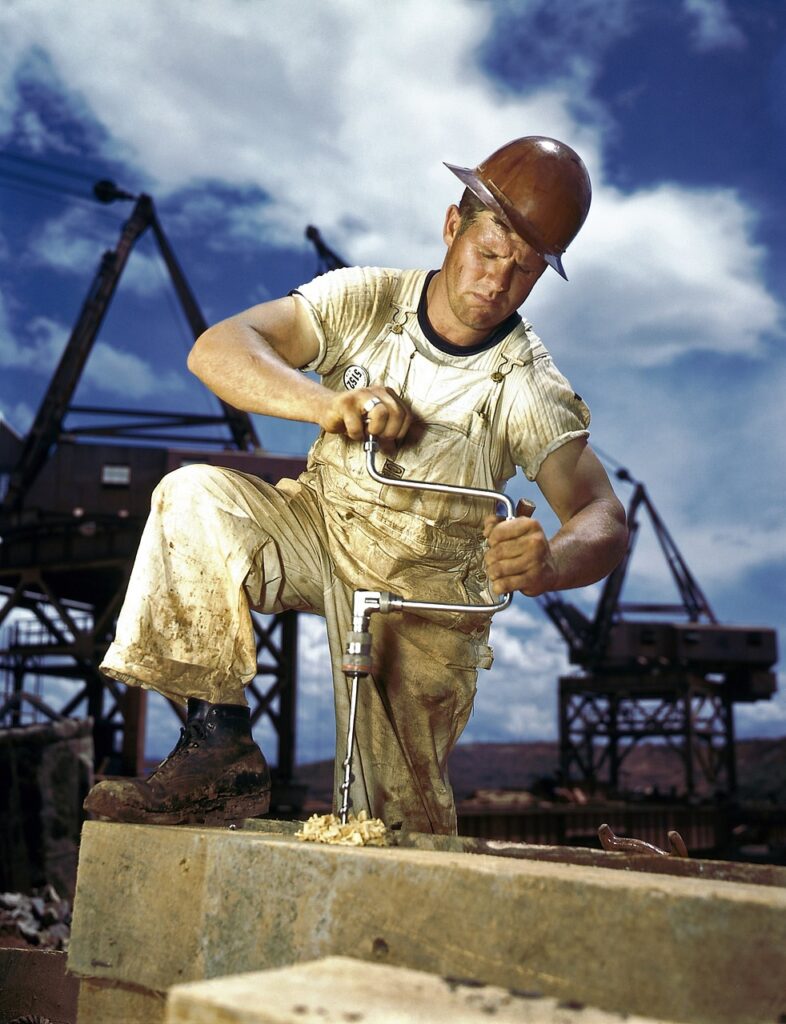

Manual metal bending tools include hand-operated devices such as metal brakes, slip rollers, and pipe benders. These tools work well for simple bends and thin materials. They are favored in small workshops and for custom or prototype work due to their low cost and portability.

The angle and shape depend on the operator’s skill. They are not suitable for thick metals or high-volume production because effort and consistency are limited. Common uses include fabrication of signage, brackets, and basic sheet metal parts.

Hydraulic Press Brakes

Hydraulic press brakes use hydraulic cylinders to apply force to the metal between a punch and die. This allows bending of thicker and tougher materials with higher accuracy than manual methods. They can bend complex shapes with consistent pressure.

These brakes are common in industrial settings due to their durability and power. Operators input parameters like bend angle and length, and the machine executes the bend. They handle high volumes and can be semi-automated but usually require skilled operators for setup and safety.

CNC Metal Benders

CNC metal benders incorporate computer numerical control for automated and highly precise bending. They are ideal for complex profiles and repeated production with tight tolerances. The machine follows programmed instructions to position the workpiece and apply force accurately.

These benders reduce manual labor and increase throughput. They are often used in mass production of automotive parts, appliances, and metal furniture components. Their software allows for quick adjustments and documentation of bend sequences.

Key Features and Considerations

Metal bending equipment requires careful evaluation of several factors to ensure optimal performance. These factors include the types of materials it can handle, the precision it offers, and built-in safety features.

Material Compatibility

Metal bending equipment must suit the thickness, type, and hardness of metals it will process. Machines designed for thin sheet metal may struggle with thicker or harder materials such as stainless steel.

Common compatible materials include:

- Aluminum

- Mild steel

- Stainless steel

- Copper

Equipment with adjustable pressure settings is better for handling various metals. Manufacturers often specify the maximum metal thickness and tensile strength the machine can bend effectively.

Precision and Output Quality

The accuracy of bends directly affects the quality of the finished product. Equipment with computerized controls (CNC) provides higher precision by automating the bending angles and repetition.

Key precision factors include:

- Angle repeatability (±0.1° or better in advanced models)

- Consistent bend radius

- Minimal material deformation or cracking

Manual machines may require skilled operators to achieve consistent output. High precision is critical for industries requiring tight tolerances, such as aerospace or automotive.

Safety Mechanisms

Safety features protect operators from injury and ensure compliance with regulations. Typical safety mechanisms include emergency stop buttons, light curtains, and protective guards.

Other important safety elements:

- Two-hand operation controls preventing accidental activation

- Overload sensors to avoid machine damage

- Clear warning labels and operational instructions

Proper maintenance and training elevate safety further. Employers often prioritize equipment with certified safety features matching workplace standards.

Leave a Reply